Lobe pumps are used in transfers of viscous products and fluids containing solid particles. Positive displacement gear pumps that do not disturb the structure of the products.

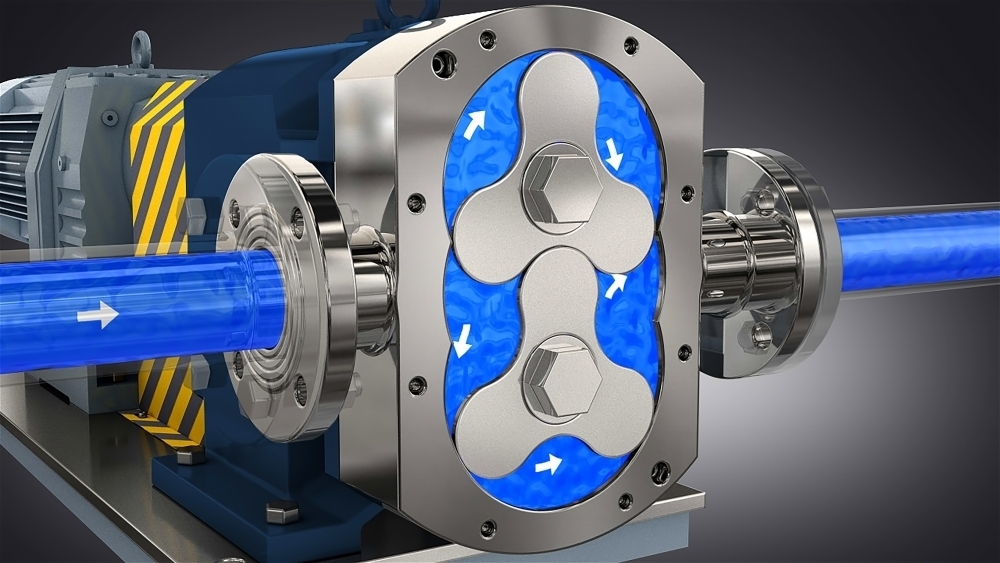

Lobe pumps consist of two lobe rotors rotating simultaneously in a casing without touching each other.

As the rotors rotate, the space between the protrusions and the casing is filled with liquid, thus providing efficient pumping.

Lobe pumps are popular in a variety of areas with their hygiene, high efficiency, safety and on-site cleanability. It is widely used in food, chemistry, paper, beverage, pharmaceutical sector. In lobe pumps, the contact of the lobes is prevented by the timing drive gears. Since there is no contact between the lobes and they have a larger pumping reservoir than other pump types, they can transfer solid particles without damaging them. The pump is connected to the shaft of the lobe, the motor receives the motion of the timer with the drive gear and the other lobe is in the opposite direction. As the lobes move in opposite directions, the volume expands at the suction opening of the pump. Through the suction obtained, the liquid flows to the pump. The liquid that is transported between the lobes and the rotorcase moves toward the discharge mouth. The liquid does not pass through the lobes. The lobes penetrate inside the discharge port and push the liquid together with the pressure. In each turn of the pump shaft, liquid is transferred as much as the volume of the pump. Therefore, the pump’s capacity is directly proportional to its size and cycle.

ADVANTAGES

- They are positive displacement pumps (allows transfer to both right and left directions)

- Various connection possibilities

- They provide trouble-free transfer in stop-and-go with their seal and heating jacket options.

- Handles the transfer of high viscosity products without any problem.

- It works silently and without vibration

- Surface materials do not rub against each other during transfer.

- Provides the opportunity to work at high temperatures

- Provides the opportunity to transfer solid particles

- Easy to clean

- Transfers smoothly without disturbing the properties of the product to be transferred.

- Provides sterilization in place (CIP / SIP) feature

WORKING PRINCIPLE OF LOBE PUMPS

Maxwor Lobe pumps in 304L or 316L stainless steel are assembled on a cast iron gearbox which has a protective coating in epoxy paint finish. The chamber separating the rotor case and gearbox enables the fitting of balanced compact reversible mechanical seals, avoiding the contamination between the pumped fluid and the gearbox lubricant. The base of the gearbox is designed to make installation easier for connecting into horizontal and vertical pipelines. Maxwor Lobe Pump is modular in design allowing the main parts such as the rotor and seals to be changed quickly and easily.

Quality and high precision working is optained through having compact and rigid mechanical parts including double conical roller bearings shafts and oversized gears running in an oil bath within the gearbox. This is to obtain smaller tolerances as the rotors do not have any compact points. This ensures a good pump performance and reliability is obtained.

In the lobe pumps the rotors rotate in an opposite direction without contact with each other. Thanks to this characteristic the metal parts do not wear and contaminate the product and there is also no damage to the product. The lobe pumps are also suitable for handling abrasive products. The transmission movement from the motor drive shaft to the driven shaft is made by double high precision gears. The timing device is simple and accessible – one gear is fixed and the other gear mounted on the bush is adjustable.

MATERIALS OF CONSTRUCTION

All shafts are made of stainless steel AISI 304L or AISI 316L. Lobes are manufactured from high quality AISI 304L or AISI 316L extruded shaped bar or special stainless steel non-shrink alloy. The pump body is also made of AISI 304L or AISI 316L stainless steel.

ADVANTAGES of LOBE PUMPS

One of the most beneficial things that a rotary lobe pump has to offer is the fact that they can handle medium sized solid particles in the pumping fluid. This is due to the fact that the lobes do not come in contact with each other and because the pumping chambers inside the pump are large enough to handle solid particles. This is an advantage for the food industry.

For example, when processing something like cherries, this type of pump is great. The cherries and fluid can move into and through the pump without being damaged or broken down. They are then sent to their desired destination. Just like the cherries, there are many different scenarios where it is crucial that the product is not negatively impacted. This could be a slurry of solid particles that need transferred from one part of the plant to another, for example.

You may also need to transfer a viscous fluid that would be broken down if it traveled through a different style of pump. The correct type of rotary lobe pump will handle the material with care.

LOBE PUMP SELECTION

While choosing the lobe pump, the features of the product to be transferred, the features of the line to be transferred, are the required technical details.

These desired values are shown in the table in detail below.

This post is also available in:

Türkçe (Turkish)

Türkçe (Turkish)