AIR SEPERATOR

Oxygen dissolved in water; is released when its temperature increases under pressure and creates air bubbles in the water. Air bubbles cause corrosion in heating systems and all plumbing pipes, and cavitation in pumps and plumbing. Bubbles adhering to heat transfer surfaces decrease heat permeability and result in loss of efficiency. It causes malfunctions in pumps and other armatures, disturbing noises in plumbing pipes and especially in radiators.

The Air Separator collects the air bubbles in the water on the surface of the specially designed metal filling material and throws them out. Thus, problems occurring in the installation and heat transfer equipment are prevented, and the system works properly.

| Body | : | St 37.2 Carbon Steel |

| Air Separator | : | AISI 304 Stainless Steel |

| Max. Working Pressure | : | 16 Bar |

| Max. Working Temperature | : | 100ºC |

| Connection Type | : | Threaded / Flanged |

DIRT SEPERATOR

Sediment and dirt in the water causes wear, low efficiency and malfunctions in heating and cooling installations, pumps and other armatures.

Cleaning and maintenance can not be done easily by the user in conventional type strainers, so cleaning is often neglected.

This negligence leads to problems such as clogging of the filters and inefficient operation of the system and consequently, not being able to heat sufficiently.

Note: A drain valve must be used for the system to operate properly and efficiently.

| Body | : | St 37.2 Carbon Steel |

| Air Separator | : | AISI 304 Stainless Steel |

| Max. Working Pressure | : | 16 Bar |

| Max. Working Temperature | : | 100ºC |

| Connection Type | : | Threaded / Flanged |

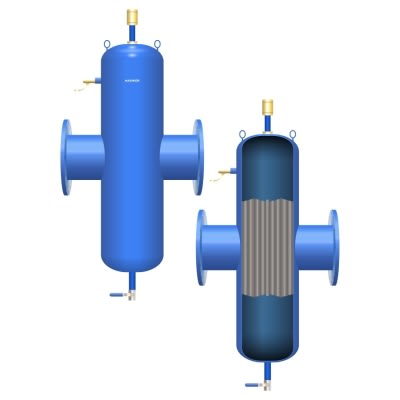

AIR AND DIRT SEPERATOR

Sediment and dirt in the water causes wear, low efficiency and malfunctions in heating and cooling installations, pumps and other armatures. Cleaning and maintenance can not be done easily by the user in conventional type strainers, so cleaning is often neglected. This negligence leads to problems such as clogging of the filters and inefficient operation of the system and, consequently, not being able to heat sufficiently.

| Body | : | St 37.2 Carbon Steel |

| Air Seperator | : | AISI 304 Stainless Steel |

| Max. Working Pressure | : | 16 Bar |

| Max. Working Temperature | : | 100ºC |

| Connection Type | : | Threaded / Flanged |

BALANCE TANK

The fluid loses heat as it returns from the installation to the boiler. This causes thermal stresses in the boiler. The main task of the balance tank is to ensure the thermal balance by mixing the cooled water coming from the installation with the water coming from the boiler. Temperature can be controlled with the sensor attached on it.

Note: A drain valve must be used for the system to operate properly and efficiently.

| Body | : | St 37.2 Carbon Steel |

| Max. Working Pressure | : | 16 Bar |

| Max. Working Temperature | : | 100ºC |

| Connection | : | Flanged / Welded End |

Balance Tank Selection

- When dimensioning, the max. heating water flow should be based.

- The water flow in the hydraulic balance tank is max. sizing should be done to 0.2 m / s.

- The pump on the primary side must be selected to overcome the resistance of the boiler and the primary side installation. The pump on the secondary side must be selected to overcome the resistances of the secondary side installation. All heating circuits on the secondary side must have separate pumps. The resistance of the balance tank is negligible.

- The flow temperature is measured by a sensor, which is welded to the secondary side, through the hydraulic equilibrium vessel.

PACKAGE BALANCE TANK

Thanks to a magnificent hydraulic balancing, an efficient operation is provided in systems where more than one or cooling group is used and multi-pump systems. Beside the hydraulic balance, it is very important to separate the air and sediment in the system. With a single product, hydraulic balance, residue and air separation can be achieved together. In this way, 4 installation connections will be sufficient instead of 8 connections. It provides an advantage in terms of both initial investment and assembly & labor costs.

Package balance tank should be placed between the primary circuit and the secondary circuit. This point is also an ideal place for air separators and dirt seperator.

| Body | : | St 37.2 Carbon Steel |

| Max. Working Pressure | : | 16 Bar |

| Max. Working Temperature | : | 100ºC |

| Connection | : | Flanged / Welded End |

Advantages

- Package balance tank is a stand-alone function for all three of the air separator,hydraulic equilibrium and sediment retention devices.

- The use of the package balance tank prevents hydraulic imbalance.

- Prevents overloading of pumps and damage caused by this load.

- Significantly improved heat transfer ensures more qualified output in the automation system.

- The package balance tank must be placed between the primary circuit and the secondary circuit. This point is also an ideal place for the air separator and sediment retainer.

This post is also available in:

Türkçe (Turkish)

Türkçe (Turkish)